On the GL1100, Honda did something very needful. They added an accelerator pump to the carburetors. Together with smaller throats, these two changes made a huge improvement over the GL1000's carb set, tuning the GL1100's carbs much closer to the way the motorcycle was actually being ridden.

The GL1100's carburetors are of a family Keihin called "VB", a designation which you can see cast into the side of each carburetor body, and a family of carbs Honda used on most of their bikes during the early 1980s. And excepting some Euro and other variations, all of the VB series carbs used during this time have accelerator pump circuits. This includes the six-cylinder CBX, the DOHC inline fours, the 650 four, the 500 and 650 and 400 twins, and even the FT500 single. All have this same accelerator pump system.

It's a good system, the accelerator pump, but it has a fault. Its discharge orifice is so tiny it clogs easily. Coupled with a very low pressure operating diaphragm, it's a cinch most GL1100s are not benefitting from all the throttle response they should be due to a weak accelerator pump system.

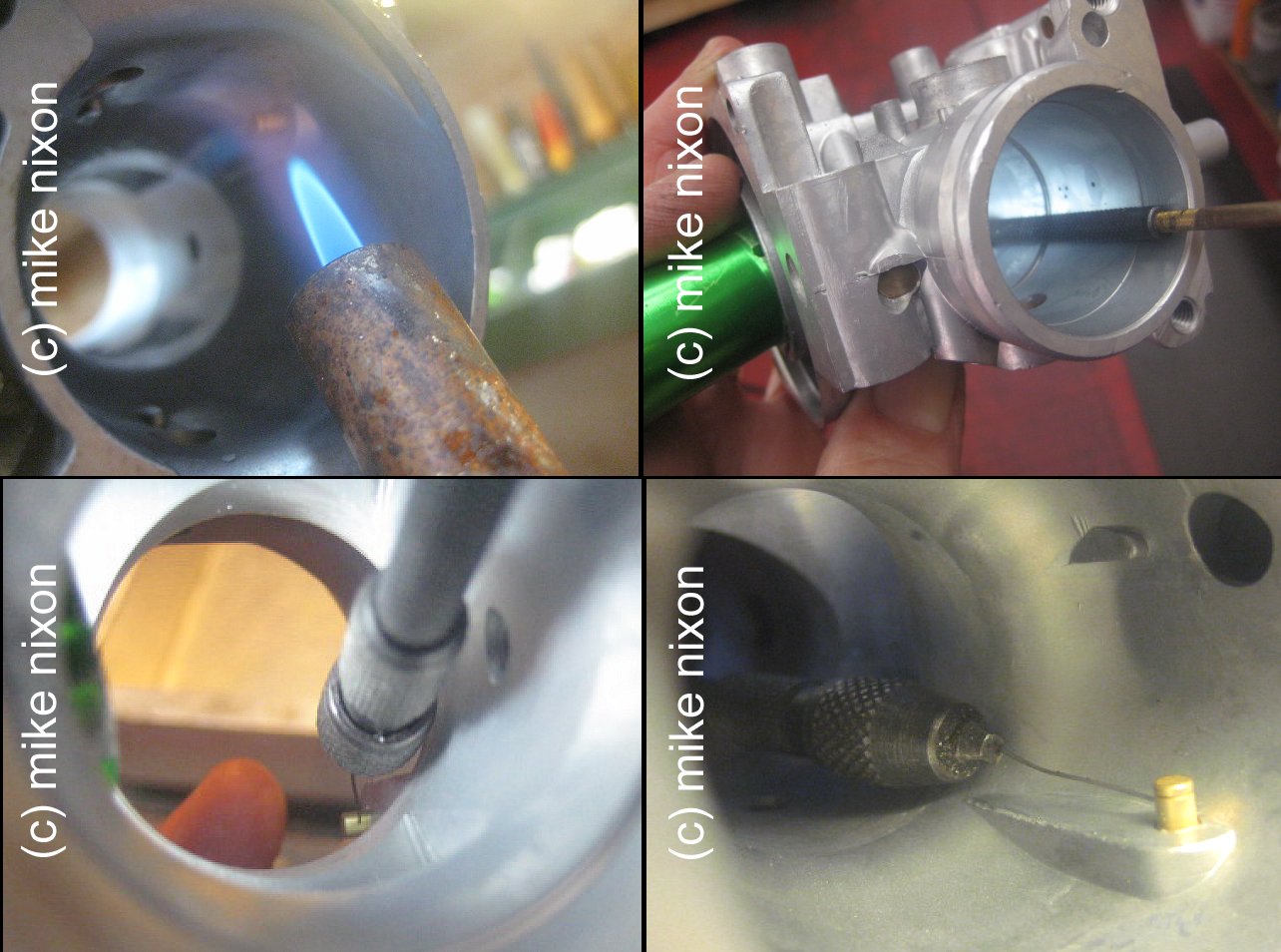

Here's how I fix that. I usually try heat first. More than half the time however it isn't enough. I have a piece of a guitar string clamped in a pin vise, which is just a handle to hold very small drills. The pin vise is extended with a piece of welding rod for better reach. After opening both the throttle and choke plates, or sometimes even removing them, I shoot a flashlight down the carb throat and at the same time ease this special tool down to the accelerator pump's upright nozzle. Once in the nozzle's discharge orifice, I rotate the tool to auger the nozzle, which dislodges any varnish or rust (usually both). I'll remove the tool and test the nozzle with an brake cleaner aerosol, and if needed, repeat with the tool. After trying hydraulic methods, heat, and more, this technique has become the one I always use, when needed, on all of the carburetors I rebuild.