You'll need;

* 1/4" solid round brass stock (ACE Hdwr)

* 5/32", 7/64" drill bits

* propane torch with rosin core solder

* shear cut cable cutter or Dremel with cut-off wheel

After measuring (important step) the original excess cable (distance between barrel to housing), cut off barrel.

A shearing style cable cutter does the best job keeping strands together. (Use dikes at your own risk.)

Route housing with the smoothest path possible. Radical twists and turns makes for a poor or hard feel at the lever. Cut excess housing. Measure twice cut once !

Don't throw that extra housing away ! Remove ferrule with a Big Ol' Cresent wrench by turning counter clockwise.

Trim back the metal spiral flex and press on ferrule. No need to re-crimp.

With housing reduced, it's on to the barrel.

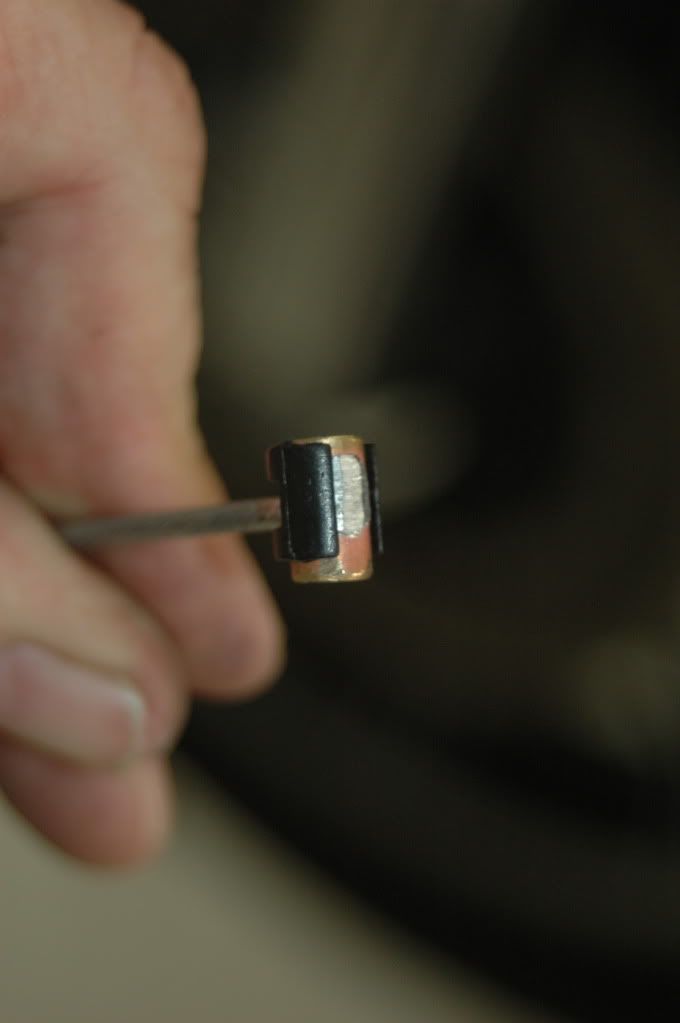

Drill an inset with 5/32''bit followed by 7/64'' thru hole in 1/4'' brass stock.

Time to re-insert cable (the correct direction). Remember that excess measurement ? Make a mark on cable were the new barrel will go. This is a good time to install the plastic bushing if your original cable had one.

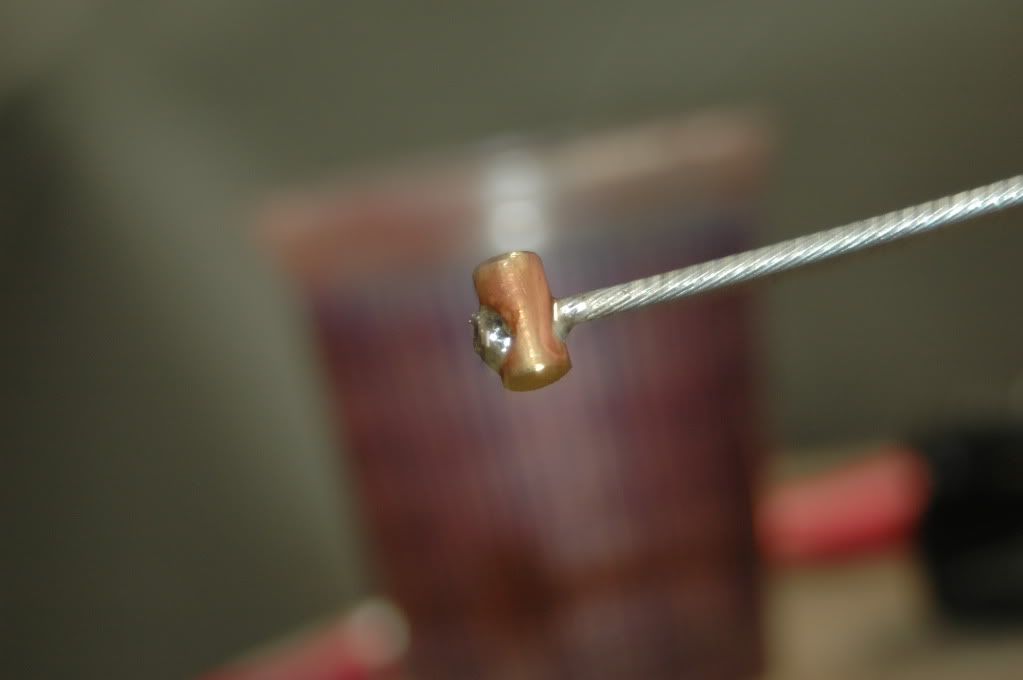

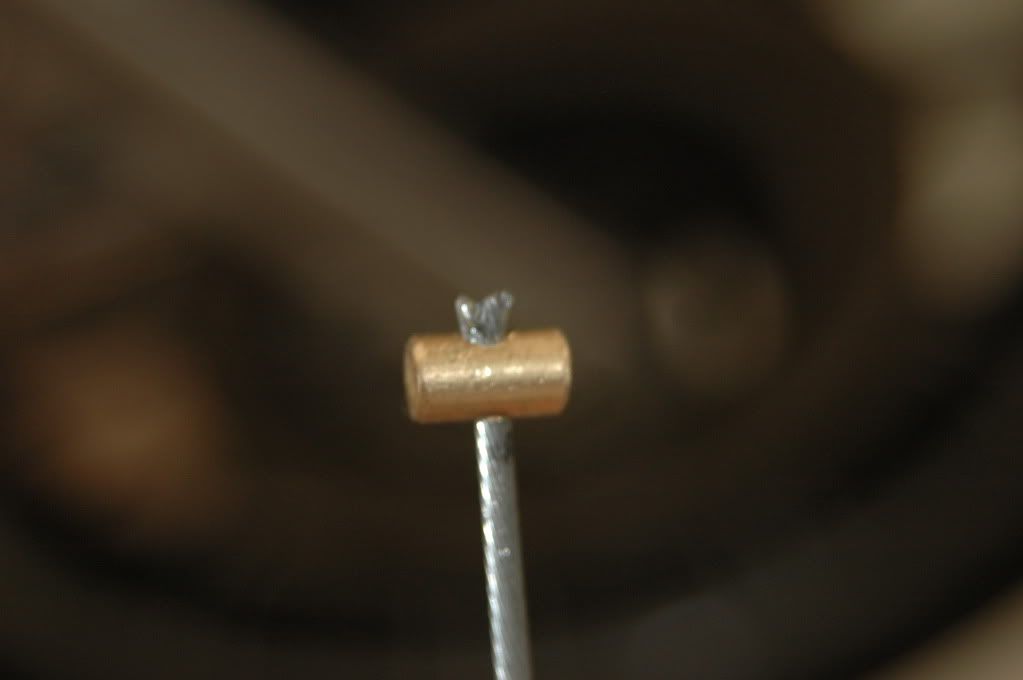

With barrel & cable trimmed to to size, Fray a small amount of cable past the barrel.

Using your torch

A perfect fit that won't slip. This technique works good on throttle cables also. Although I must confess sometimes I use knarps