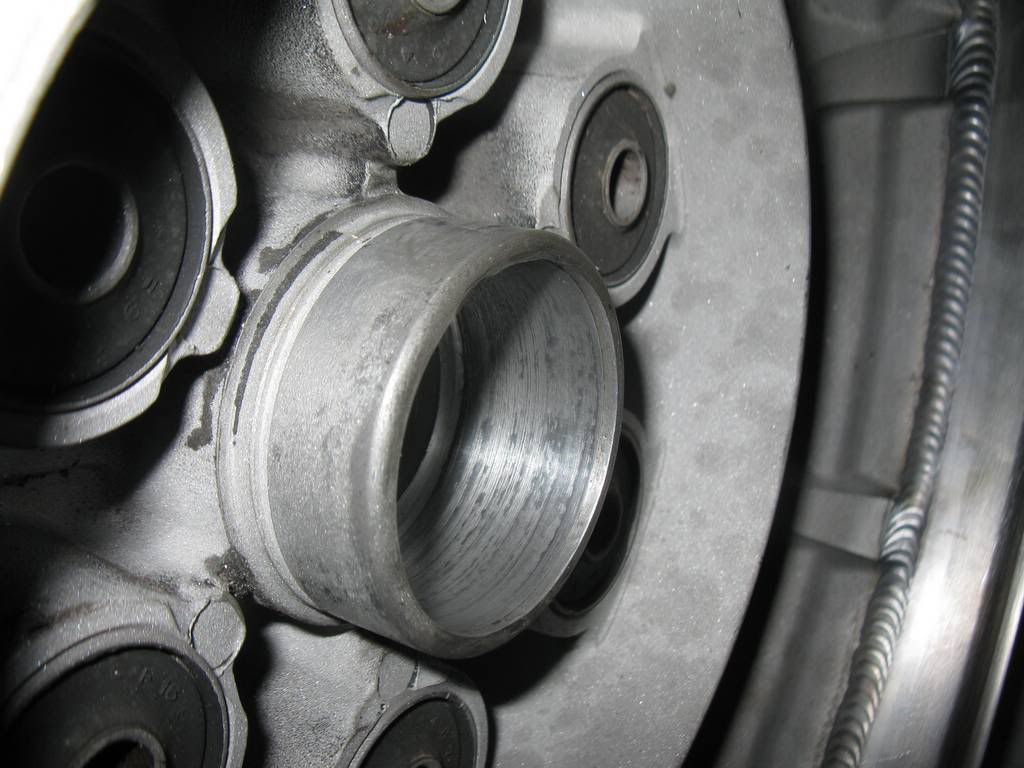

GL1200 Rear Wheel Bearings themselves do not ...usually... fail. What fails is the underengineered bearing support on the drive side, which becomes egg shaped and allows the wheel to go wonky and the bearing moves inside the egg shaped hole. The wheel can move around enough to allow the tire to contact and rub the swingarm...

Here is a pic of an early wheel with a shop fix; the knurls raise the surrounding aluminim a bit so the bearing fits tighter. But as you can see, over some period of time the little raised sections of aluminum finally wear down. This may be a cheap fix, but it is also not permanent.

Here is a pic (from Saunders Site I believe) with a machined SS bearing insert inside a milled out bearing hole. But the forces are still only countered by a now-thinner section of aluminum bearing support.

Mother Honda did 3 fixes for this. a) Under warranty they would turn the wheel and replace the bearing with a larger disk side bearing, which did nothing to solve the problem. b) Mod 1 wheel, and c) Mod 2 wheel. So AFAIK, there are now at least three different styles of GL1200 wheels, and two types of spiders.

1. Style 1 wheel is "tall and hollow", and I am guessing is the original version. The aluminum extension that houses the bearing is "tall", and the hub inner section is "hollow". The 2 pics above reflect the Style 1 Hubs. We came up with the idea of a machining a full hub-width sleeve with bearing stops machined in. Tack weld insert to hub on disk side, then full weld-up on drive side with machining out the bearing area. But this would take a lot of machining time... Alternatively, if you can weld stainless to Al, make the insert out of 316SS; but this may be easier said than done...

Note: This Style uses a Spider with "tall" skirt that covers the extension that houses the bearing.

2. Style 2 wheel is "tall with reinforced hub". I am guessing this was Mod 1. There is more wall thickness in the hub (not the bearing extension), and I am guessing that some engineer calculated that it would help to reinforce the area that was NOT stressed

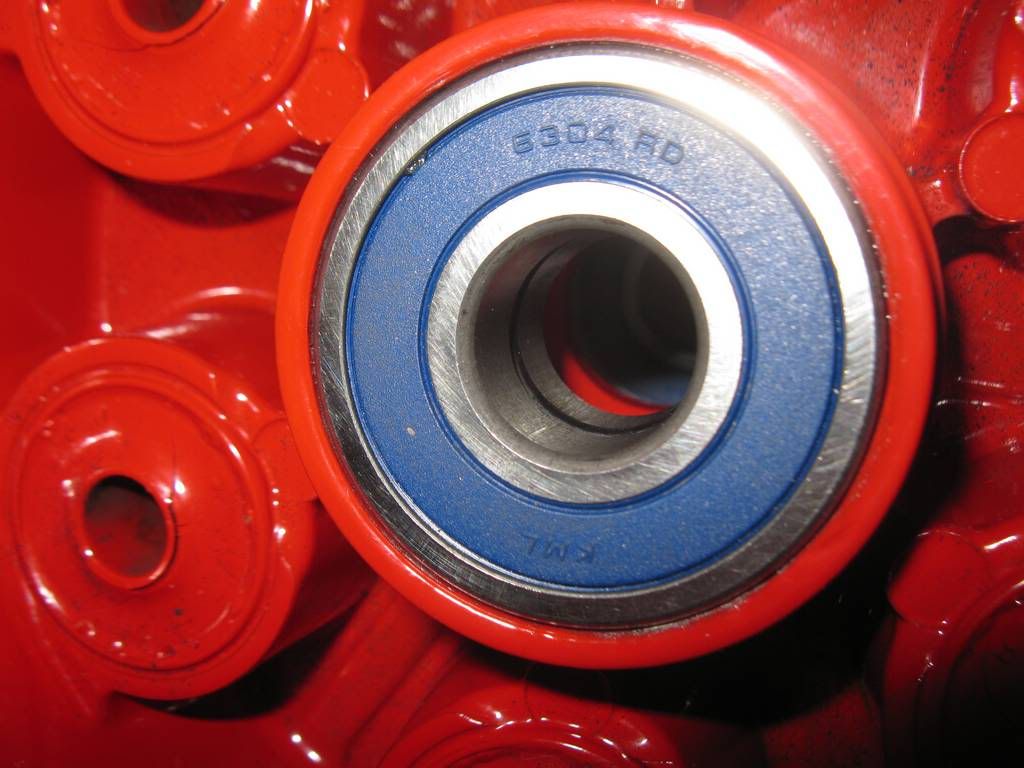

3. Style 3 wheel is "short with reinforced hub". I am guessing this was Mod 2. It has the inner reinforced hub identical to Style 2, but the aluminum bearing support that extends out is shorter, as it has been slightly recessed INTO the reinforced hub area. This would tend to minimize the forces on the bearing extension, and it is definitely the strongest of the lot; but apparantly (still) not strong enough. The latest wheel I got from ebay was this type, and I pressed the new bearing in with my fingers... The good news is that this wheel can also be repaired identically to Style 2 wheel. Note: This Style uses a Spider with a "short" skirt that covers the shorter extensionthat houses the bearing. These pics also reflect the final machining we did to accommodate double bearings (bearing size same as disk side).

4. Short and tall Spiders are NOT interchangeable. However, it's pretty easy (with a mill or lathe) to turn a "tall skirted" Spider into a "short skirted" Spider; harder to go the other way...

5. I'm pretty confident this will solve the problem for good on the Style 2 and 3 wheels, and it is not expensive for the machining. We used a manual mill, but a big block lathe would work as well. If I had a Style 1 wheel, I would turn it into a lamp base and get a Style 2 or 3 from ebay; I've paid from $40 to $100.

6. If anyone with a wheel problem wants to skip all this, it appears that a GL1500 wheel, disk, pumpkin, and caliper mounting bracket will all bolt-up with some simple hand tool mods. You'll gain the double width drive side bearings, as well as a 16" wheel size. The GL1500 rear wheel won't match the GL1200 front however, so you may look a little dorky...