A lot has been written about melted alternator connectors. Unfortunately, most of it seems to miss the point and fails to help people prevent either the problem occuring in the first place or recurring after the repair. Although I posted on this subject before, it's time to look at it a little more thoroughly. Wait! Mike's getting senile, he's repeating himself! Not quite.

Powersports vehicle wiring harnesses figure more heavily in maintenance issues than they should. When with corporate Kawasaki I learned that on any given model year the vendors making the wiring harnesses for Kawasaki products were either experiencing harness manufacturing issues or taking steps to recover from bad harnesses. It was a pretty big deal.

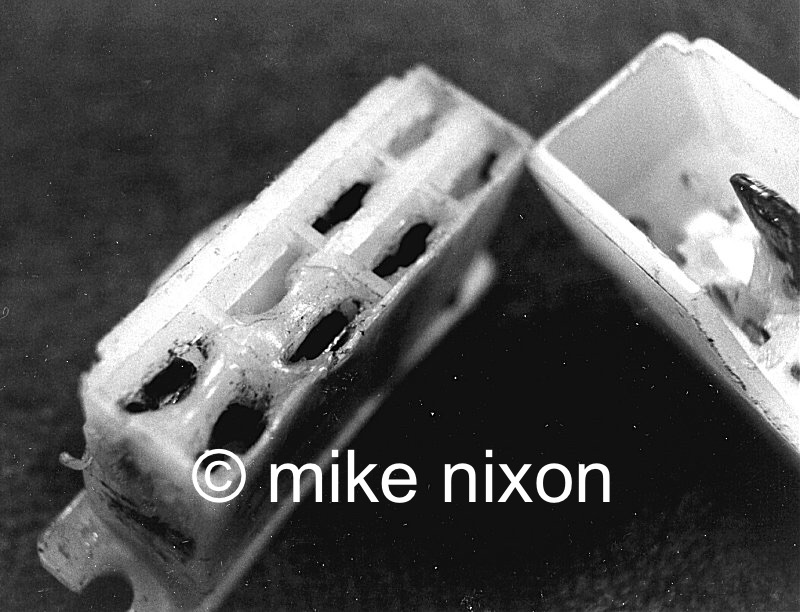

Most manufacturers have issues in their wiring harnesses. And even Honda, 50 and more years ago, did things that are now proving to not have been the best idea. One thing Honda and all manufacturers did and still do is crimp all the terminals on the ends of their harnesses. Though accepted practice in many fields associated with electrical components, on motorcycles it has been demonstrated that they are an exception; crimping isn't such a good idea. With pretty much wide open exposure to the elements, the crimps begin to corrode, and the corrosion starts to interfere with electrical currect -- this is called resistance -- and pretty soon instead if being merely a *carrier* of electical current, these crimped terminals instead become *consumers* of current, absorbers if you will. This shouldn't be and it is where the heat that melts the connectors comes from. It doesn't come from the alternator. It doesn't come from the engine, It doesn't come from the wires. It comes from within the connector itself. The connector heats itself up and melts. Imagine the filament in your headlight. Hot, right? Corrosion inside a canon plug is the same as that headlight's filament. Both turn current into heat.

One example of how bad this got was Honda fuseboxes. At first Honda crimped the fusebox terminals just as with everywhere else in the wiring harness. But fuses started getting hot, and if left to themselves the plastic fuseboxes simply melted. This still is a big problem on vintage Honda CB750s. Even after Honda in response began soldering the backs of the fuseboxes, the quality of the soldering was hit or miss and the trouble persisted, eventually leading to a recall on the more heavily-wired 750 Automatic model that is still in effect today.

In fact, on every Honda I have owned, and every customer bike I do any electrical work on, I inspect and service two canon plugs: the one at the alternator and the one at the fusebox. These are the highest current-carrying canon plugs on the motorcycle. Do the job preemptively or do it as repair. Either way you'll be done with it and you'll never have melting connectors there again.

The design of motor vehicle connectors ultimately was changed because of this corrosion problem. As fuel injection and onboard computers started appearing on bikes in the late 1990s, wiring harness manufacturers started changing over to the European spec connector (DIN), which is rubber-sealed and tighter-fitting. The common name for these is "waterproof". The terminals inside are still crimped onto their wires, but at least now the silicone rubber seals limit their exposure to air and moisture and thus delay corrosion far longer than before. Almost perfect.

So, switch all your connectors over to waterproof type? No, not very practical. Or necessary. Because you can do the next best thing. Here's your action plan.

Solder over the crimps. You'll need to extract each terminal from its canon plug (requires a special tool), clean the terminal as best you can, dab it with soldering flux, and solder it. This by itself seals the crimps from corrosion. It's a permanent fix. But we'll do even more.

Put the terminals back into the canon plug, replacing the plug if needed due to its melting. Many sources for these exist.

Then, to limit the connector's exposure to the atmosphere, pack grease all through the connector halves before rejoining them. This in effect upgrades the old open-backed canon plug to the sealed spec of the Euro connector. Any kind of grease is better than no grease, but the best is a grease rated as "dielectric", meaning it has no conductive metallic elements in it, such as is common for example in lithium grease.

This is the best and only permanent, serviceable repair. Unlike simply soldering the wires together it allows the normal serviceability intended by the factory. And unlike simply replacing the cannon plug it proactively solves the actual problem, never to return again.